Reusing And Creating More Possibilities For Circular Value

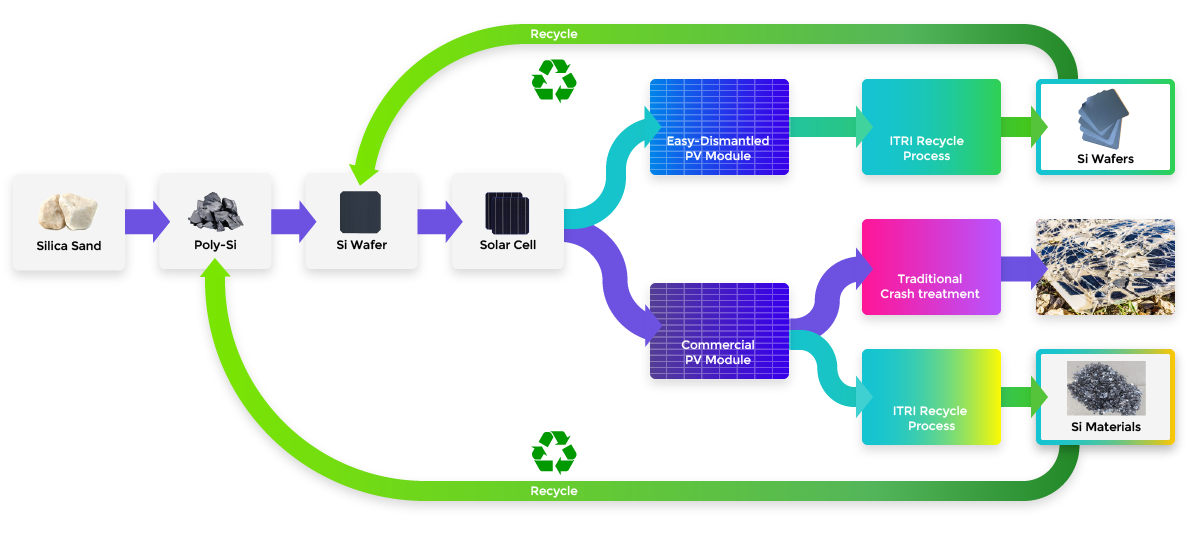

Since the introduction of solar modules in 2000, global solar installations have enjoyed an average annual growth rate of 42%. Due to the lifespan of solar modules, we can expect there to be a large number of older modules that need to be discarded in 2030. However it is a challenge to properly process and recycle solar module components, which are tightly sealed together early in the module manufacturing process. Solar module redesign will be a major change for the industry as it marches toward the Net Zero future.

Our Solutions

Innovative solutions

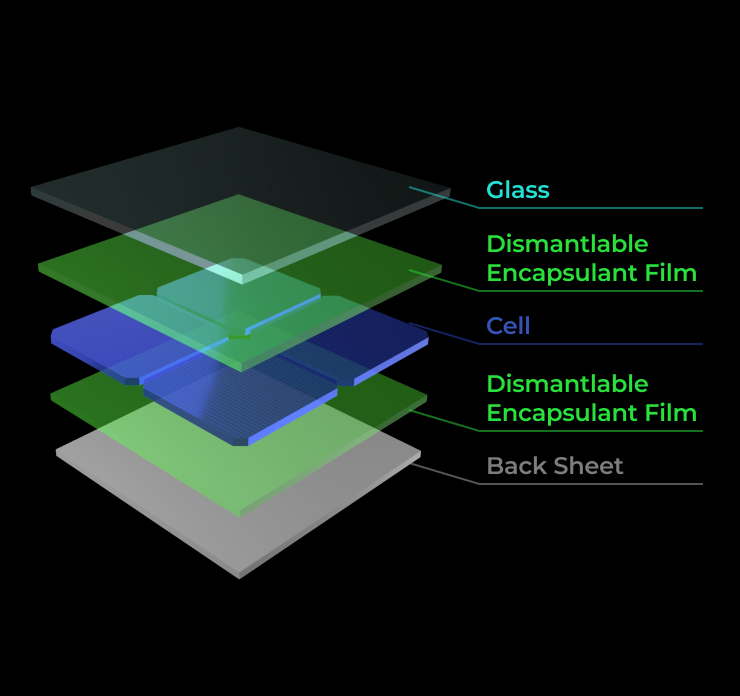

Eco-redesign of sustainable PV modules is true to society, which can economically recover most of the components of the PV modules. Easy-dismantling PV modules are environmentally sustainable products with beneficial ways to society. Easy-dismantling PV modules provide a new recycling system with the glass and solar cells intact. The module restored highly pure raw materials and regenerated them into raw materials for new modules. The new end-of-life management for the modules creates revenue and provides economies-to-environment benefits.

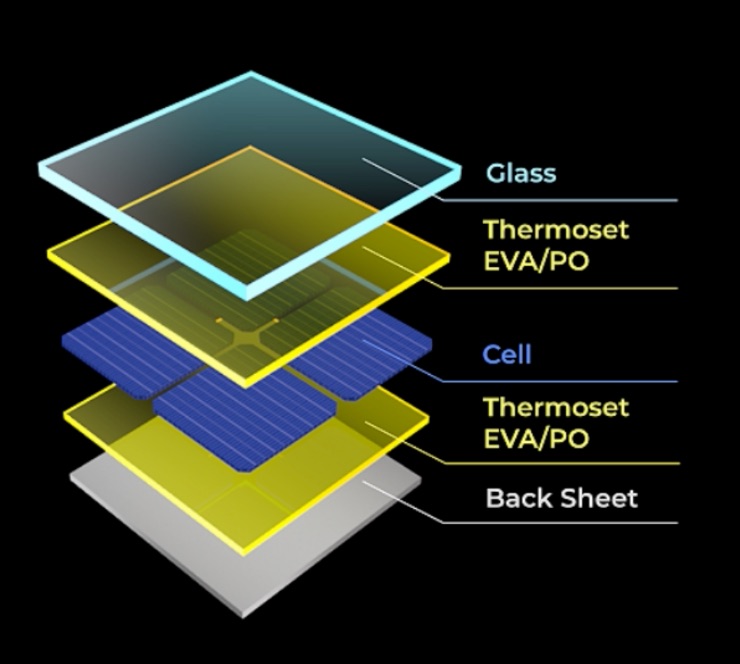

Commercial PV Module Solutions

Unlike traditional shredding methods, commercial PV modules are separated through physical disassembly and pyrolysis processes. And it can be peeled off with high cleanliness and completeness, and the cover glass can be recycled and reused. The separated solar cell fragments can also be recycled and converted into 6N silicon as a raw material for silicon growth. Create greater carbon reduction and recycling value.

Solar Mount Solutions

Non-toxic and high-durability corrosion-coated solar mounts have passed non-toxic tests such as BPA and RoHS, and do not produce environmental or human harmful substances. The product has passed the 4200-hour accelerated corrosion test of the EU IEC 60068 method, with excellent coating adhesion and no rust, suitable for harsh environment applications.

Carbon Reduction Of

PV Module Solutions

More Carbon Emission Reduction Benefits

In the fabricating process of a PV module, 43% of carbon emission come from the poly-silicon material. Recycling of the silicon materials from 1GW commercial PV module and re-used in PV crystal growth can reduce 86780 tons carbon emission. However, recycling of the silicon wafers from 1GW easy dismantle PV modules and re-used to making new solar cells can reduce carbon emission as high as 760000 tons.

Solar Module System Cycle Carbon Reduction Solution Benefit.

Maximize

Recycling Value

Reduce

Earth Waste

Reduce

Carbon Emissions

Meet the

National Carbon

Reduction Standard

Achieving

Corporate Carbon

Reduction Plans

Join our 2022 Webinar

Carbon Reduction Solutions - Innovative Solar Module & System Technologies

AM9:00 (WET)

About Us

MCL(Material and Chemical Research Laboratories), based on key industrial demands and value chains and integrating with domestic and foreign academia, strengthens cooperation with the industrial community. MCL focuses research in the development of specialty chemicals and a suitable business model to develop new companies with materials enabled technologies, which will form a unique global innovative specialty chemicals / materials enterprises system.

Contact Information

Industrial Technology Research Institute.

Tang-Xi, Yu / Project Coordinator

tangxi@itri.org.tw