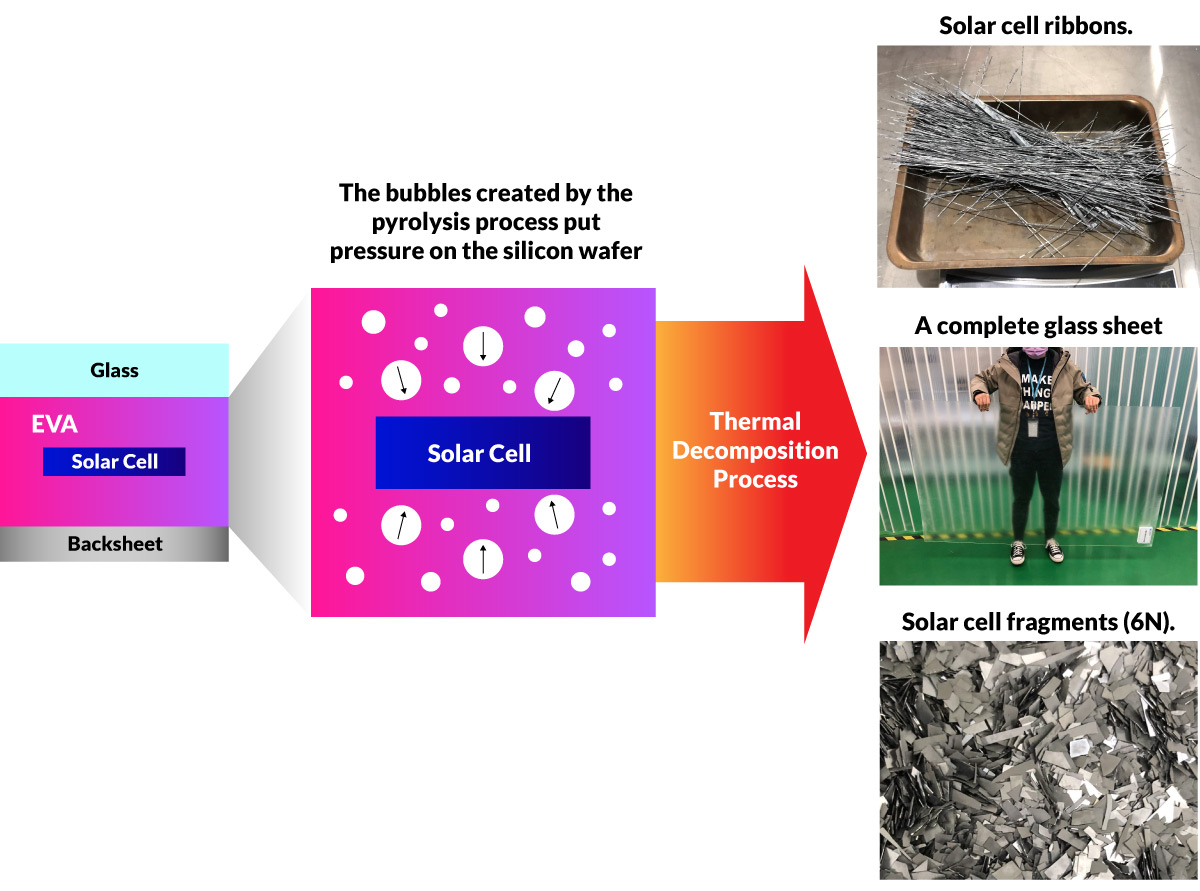

Commercial PV Module Structure

PV modules include 65-75% of glass, 10-15% of aluminum frame, 10 % of plastic, and 3-5% of crystalline silicon solar cell. 85% of these components can be recycled for reuse. However, conventional PV module manufacturing uses thermoset ethylene-vinyl acetate (EVA) or polyolefin (PO) encapsulation materials which tightly bonds the materials together, making individual component recycling and recovery extremely difficult. How to cleanly separate the components and individually recycle them is a significant task for various nations.

Preface of Commmercial

PV Module Solutions

Since the introduction of solar modules in 2000, global solar installations have enjoyed an average annual growth rate of 42%. Due to the lifespan of solar modules, we can expect there to be a large number of older modules that need to be discarded in 2030. However it is a challenge to properly process and recycle solar module components, which are tightly sealed together early in the module manufacturing process. Solar module redesign will be a major change for the industry as it marches toward the Net Zero future.

Carbon Footprint Of

Materials For A PV Module

The crashing and sorting process for commercial PV module can only reduce 53000 mt carbon emission, which is only contributed by aluminum frame. For easy-disassemble PV module, not only the aluminum frame could be recycled, the Si wafer and cover glass plate could be separated and re-generated. The total carbon reduction could be as high as 151000 mt.

Carbon Reduction Advantage

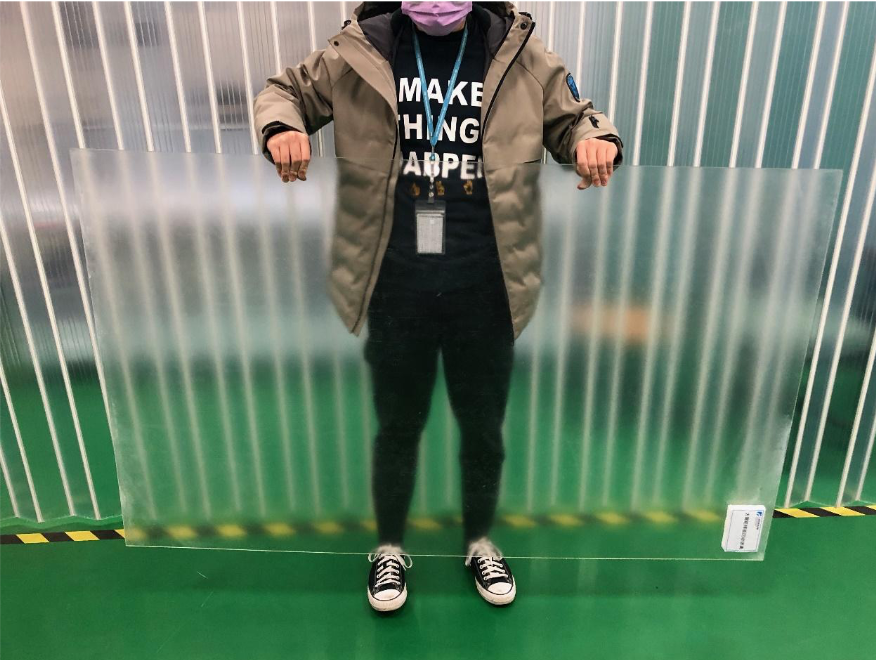

Complete glass panels can be removed from the commercial PV module.

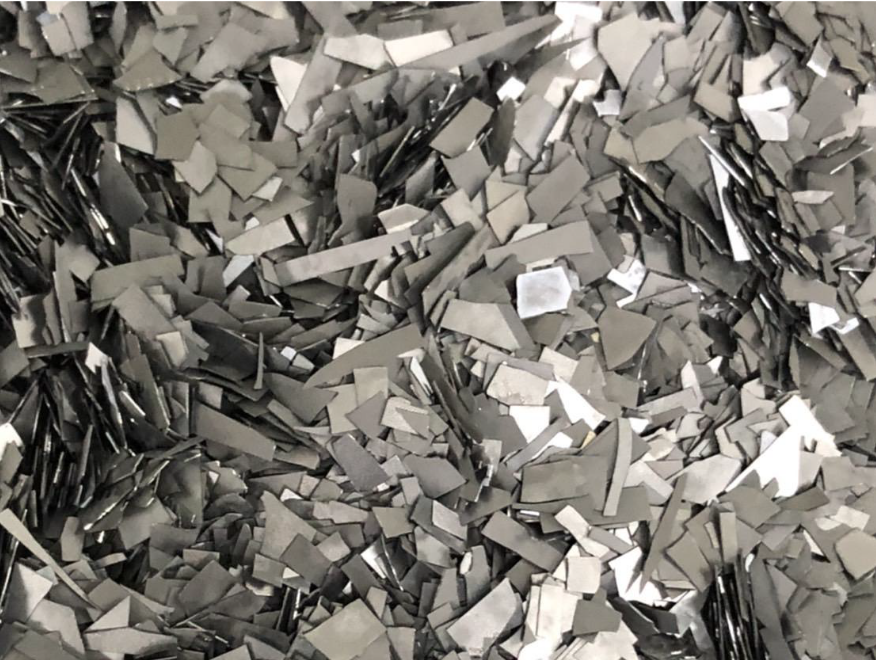

The solar cell fragments can be recycled from the commercial PV Module and repurposed into 6N purity recycled silicon materials.

The silver on the solar cells surface could be recycled.

Compared to crash treatment process, the ITRI process can reduce 142,000 tons CO2 by reusing the reclaim materials from 1 GW PV modules.

About Us

MCL(Material and Chemical Research Laboratories), based on key industrial demands and value chains and integrating with domestic and foreign academia, strengthens cooperation with the industrial community. MCL focuses research in the development of specialty chemicals and a suitable business model to develop new companies with materials enabled technologies, which will form a unique global innovative specialty chemicals / materials enterprises system.

Contact Information

Industrial Technology Research Institute.

Tang-Xi, Yu / Project Coordinator

tangxi@itri.org.tw