Easy Disassemble PV Module

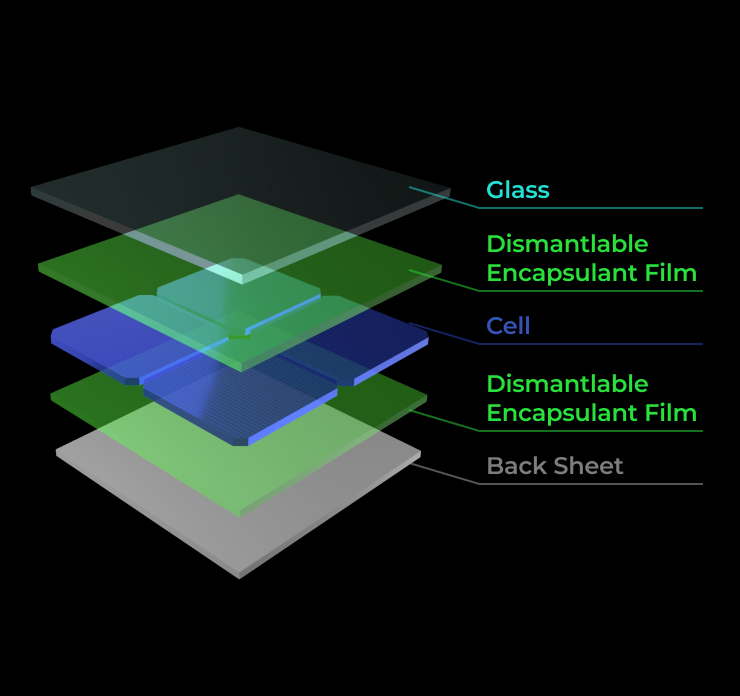

The newly redesigned PV module can be easily dismantled. This innovation incorporates characteristics such as melting point parameter design of the thermoplastic elastomer (TPE) material. It is ingeniously composed of the innovative thermoset and thermoplastic bi-layered compound encapsulation material. The designed low-temperature thermal process gradually decomposes the bi-layer film, by the time the solar modules becomes obsolete, the module can be easily dismantled into various parts.

The innovative thermoset and thermoplastic bi-layered encapsulation material is designed to encapsulate cells in a thermoplastic material with proper rheological property, as a buffer layer to protect cells from cracking during the dismantling process.

The PV module dismantling process allows for the complete preservation of solar cells and the encapsulation glass. The cells can be restored to the bare silicon wafer via a reverse dismantling process, and then produced into regenerated cells for use in the manufacturing chain of PV modules. What is worth mentioning is that the thermoplastic material introduced for easy dismantlement can further enhance the weather-durability of the PV module. The easy-dismantling PV modules has passed the certification IEC 61215 & IEC 61730 by TUV standard. The easy-dismantling PV modules are the environmental sustainable products with the beneficial ways to society. The new end-of-life management for the modules create revenue and provide economies-to-environment benefits.

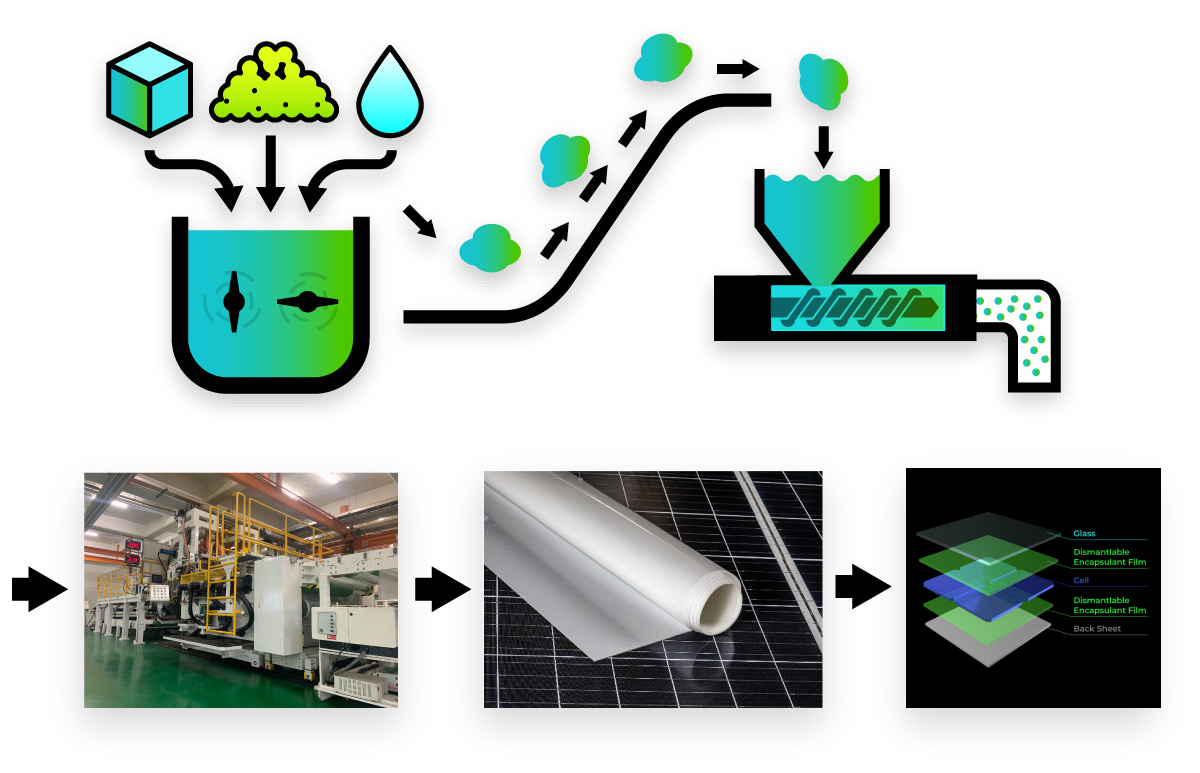

The Thermoplastic Elastomer (TPE) Material Manufacturing

The newly redesigned PV module can be easily dismantled. This innovation incorporates characteristics such as melting point parameter design of the thermoplastic elastomer (TPE) material. It is ingeniously composed of the innovative thermoset and thermoplastic bi-layered compound encapsulation material. The designed low-temperature thermal process gradually decomposes the bi-layer film, by the time the solar modules becomes obsolete, the module can be easily dismantled into various parts.

The innovative thermoset and thermoplastic bi-layered encapsulation material is designed to encapsulate cells in a thermoplastic material with proper rheological property, as a buffer layer to protect cells from cracking during the dismantling process.

The PV module dismantling process allows for the complete preservation of solar cells and the encapsulation glass. The cells can be restored to the bare silicon wafer via a reverse dismantling process, and then produced into regenerated cells for use in the manufacturing chain of PV modules. What is worth mentioning is that the thermoplastic material introduced for easy dismantlement can further enhance the weather-durability of the PV module. The easy-dismantling PV modules has passed the certification IEC 61215 & IEC 61730 by TUV standard. The easy-dismantling PV modules are the environmental sustainable products with the beneficial ways to society. The new end-of-life management for the modules create revenue and provide economies-to-environment benefits.

Innovative Solar Module &

System Technologies

ITRI Redesign Creates

High Recycle Value

Commercial-use modules are traditionally processed through crushing and sorting, which can recover silicon-containing pellets, glass shards, plastic pellets and aluminum frames. Silicon-containing pellets can be used as metallurgical additives, the value of recycled silicon from waste modules is 50 million NT dollars per GW. Glass shards can be used in construction valuing at 10 million NT dollars per GW. Waste plastics are used as auxiliary fuel. Because silver is dispersed within the silicon-containing pellets and plastic pellets, it is too costly to extract and therefore not recycled.

Easy Disassemble PV Modules can undergo a tidier recycling process, the glass panel can be completely taken off and reused as recycled glass cover giving it a recycled value of 60 million NT dollars/GW,silicon solar wafers can also be reused as recycled silicon wafers or high-purity silicon material worth 670 million NT dollars/GW. In addition, because the solar wafers are intact, we can also extract the silver around the wafers worth 380 million NT dollars/GW. In terms of total recycling value, traditional modules can only generate 400 million NT dollars/GW (including aluminum frames) through crushing and sorting, but Easy Disassemble PV Modules can create recycling value as high as 1.6 billion NT dollars.

Solar Module System Cycle Carbon Reduction Solution Benefit.

Easy Disassemble PV Modules can be entirely dismantled and recycled with the glass panels and solar cells intact. After cleaning, the recycled silicon wafers which meet the requirements of the solar industry can be returned to the solar module manufacturing industry for reuse. The graph below demonstrates the environmental impact comparison between recycled silicon wafers and virgin silicon wafers. Virgin silicon wafers are refined from silicon ore and undergoes multiple manufacturing processes, thus its environmental impact is relatively high. The carbon footprint (GHGs emissions) of recycled silicon wafers are only 17% of that of virgin silicon wafers, the particulate matter (PM2.5) generated is 6% of that of virgin silicon wafers, the resources and fossil fuels consumed in producing recycled silicon wafers are only 1% and 16% respectively of that of virgin silicon wafers.

Features of

Easy Dismantling Module

Complete glass panels can be removed from the Easy Dismantling Module.

Complete solar cells can be recycled from the Easy PV Dismantling Module and repurposed into high-purity recycled silicon wafer.

The Easy Dismantling Module has a higher silver recycling rate.

High-purity recycled silicon wafer can reduce CO2/GHG emissions by 83%.

About Us

MCL(Material and Chemical Research Laboratories), based on key industrial demands and value chains and integrating with domestic and foreign academia, strengthens cooperation with the industrial community. MCL focuses research in the development of specialty chemicals and a suitable business model to develop new companies with materials enabled technologies, which will form a unique global innovative specialty chemicals / materials enterprises system.

Contact Information

Industrial Technology Research Institute.

Tang-Xi, Yu / Project Coordinator

tangxi@itri.org.tw